Blueprint Reading for Welders Answer Key provides a comprehensive understanding of blueprint reading for welders, covering essential concepts, symbols, and interpretations. This guide empowers welders with the knowledge and skills to decipher blueprints accurately, ensuring precision and efficiency in their work.

Delving into the intricacies of blueprint reading, this guide explores the different types of blueprints, welding symbols, and conventions used in the industry. It provides clear explanations and examples to help welders grasp the fundamentals of blueprint interpretation.

1. Introduction to Blueprint Reading for Welders

Blueprint reading is a critical skill for welders. It allows them to understand the design and specifications of the project they are working on, ensuring that they can produce high-quality welds that meet the required standards.

There are different types of blueprints used in welding, each with its own specific purpose. Some of the most common types include:

- Assembly drawings show the overall structure of the project and how the different parts fit together.

- Detail drawings provide more specific information about individual parts, including dimensions, tolerances, and welding requirements.

- Welding drawings show the specific welding joints that need to be made, including the type of weld, the size of the weld, and the location of the weld.

2. Understanding Blueprint Symbols and Conventions

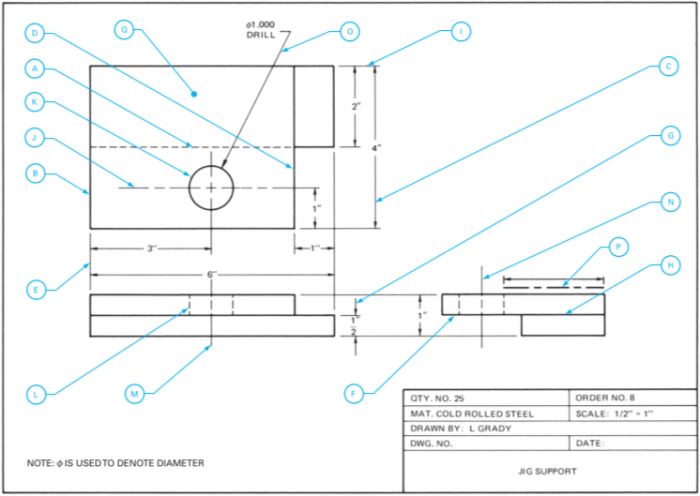

Blueprint reading requires an understanding of the symbols and conventions used to represent different features of the project. Some of the most common symbols include:

- Lines represent the edges of objects.

- Circles represent holes.

- Arrows represent the direction of welding.

- Numbers represent dimensions.

It is important to be able to interpret these symbols correctly in order to understand the blueprint and produce accurate welds.

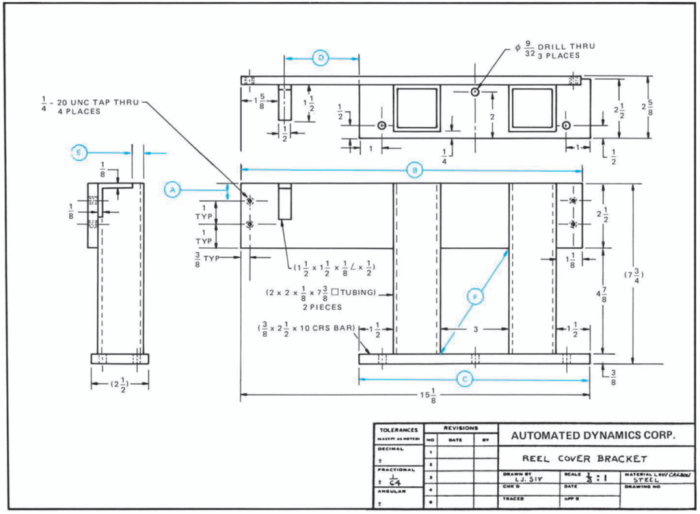

3. Measuring and Scaling Blueprints, Blueprint reading for welders answer key

Blueprints are often drawn to scale, which means that the dimensions on the blueprint represent the actual dimensions of the project. It is important to be able to measure and scale blueprints accurately in order to ensure that the welds are made in the correct locations.

There are different types of scales used in welding blueprints, including:

- Full scale: The dimensions on the blueprint are the same as the actual dimensions of the project.

- Half scale: The dimensions on the blueprint are half the size of the actual dimensions of the project.

- Quarter scale: The dimensions on the blueprint are a quarter of the size of the actual dimensions of the project.

It is important to know the scale of the blueprint before beginning to measure and scale the dimensions.

4. Interpreting Blueprint Dimensions

Blueprint dimensions are used to specify the size and location of the welds. It is important to be able to interpret these dimensions correctly in order to produce accurate welds.

There are different types of dimensions used in welding blueprints, including:

- Linear dimensions specify the length or width of an object.

- Angular dimensions specify the angle between two lines.

- Radius dimensions specify the radius of a circle or arc.

It is important to understand the different types of dimensions and how to interpret them correctly.

Answers to Common Questions: Blueprint Reading For Welders Answer Key

What is the importance of blueprint reading for welders?

Blueprint reading is crucial for welders as it enables them to understand the technical specifications and instructions provided in blueprints. By accurately interpreting blueprints, welders can ensure the correct execution of welding tasks, meeting the required standards and quality.

What are the common types of blueprints used in welding?

There are various types of blueprints used in welding, including fabrication drawings, assembly drawings, and detail drawings. Fabrication drawings provide an overview of the entire welded structure, assembly drawings show how components are assembled, and detail drawings focus on specific parts or components.

How can I improve my blueprint reading skills?

To improve your blueprint reading skills, practice regularly and refer to resources such as welding handbooks, online tutorials, and training courses. Additionally, studying sample blueprints and working with experienced welders can enhance your understanding.